SIG-C

High-speed

Bundling

Up to 32 bundles per minute to maximize production capacity

Lowest Cost of Ownership

Robust machine design coupled with low maintenance simplicity to minimize costs

Operator-

friendly

Intuitive icon-driven controls enable fast bundle set-up

Maximum

Uptime

Automatic strap loading, discharging at the end of a coil and refeed technologies minimize downtime for continuous strapping

SIG-C Automatic Corrugated Bundler

The SIG-C automatic corrugated bundler provides high speed bundling capabilities for flexo-folder corrugated products. The SIG-C is manufactured with intuitive features to ensure continuous strapping and maximum uptime.

Features and Benefits

- Minimizes production interruptions

From auto refeed that can refeed the strap up to 3 times to end-of-strap monitoring with auto ejection, the SIG-C has standard built-in features to keep production downtime to a minimum. Extra long strap coils with nearly 42% more strap coupled with quick-change dispensers reduce coil changeover frequency and downtime. - Simplifies maintenance requirements

For easy troubleshooting, the SIG-C is equipped with patented easy access strap guides that require no tools for entry. Plus, a segmented strap chute with a lifetime warranty on the flaps and one wear part eliminate costly repairs and maintenance downtime. - Provides production versatility

The SIG-C has built-in features including a low tension strap ejector, segmented chute and ultra low tension to streamline production changes, while helping to minimize product indentations from strapping.

SIG-C Options

- Spare magnetic strap dispenser

- Spare parts kit

- Industrial interlock kit

- High leg kit (40"-49")

- Low leg kit (25.2"-31")

- Floor rails

Technical Specifications

| Cycle Rate Per Minute (Max) | 32 bundles without compression 27 bundles with compression |

| Conveyor Speed | Variable from .19 to .97 m/sec (.65 to 3.2 ft/sec) |

| Strap Tension | Variable up to 311 N (70 lbs) |

| Strap Material | Polypropylene 5 mm embossed |

| Strap Seal Method | Heat seal |

| Electrical Requirement | Americas: 460 Volt, 16 AMP, 60 Hz EMEA: 100-240V, 1 AC, 47-63Hz; 380-520V, 3AC Optional 3AC; 47-63Hz |

| Pneumatic Requirement | 620.5 kPa (90 psi) |

| Pneumatic Consumption | 3998 cubic cm (244 cubic inch) per cycle (free air) |

| Environmental Condition | 4.4° to 37.7° Celsius (40° to 100° Fahrenheit) |

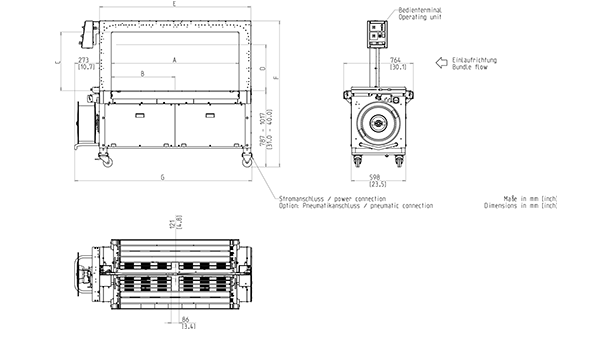

Machine Dimensions

| SIG-C 1650 | SIG-C 1250 | |

| Frame Size W x H | 1650 mm x 600 mm (65" x 23") | 1200 mm x 600 mm (49" x 23") |

| Part Number | x55001 | x46000 |

| Total Width Including Strap Coil A | 2362.2 mm (93") | 1955.8 mm (77") |

| Total Height B | 1562.1 mm to 1790.7 mm (61.5" to 70.5") | |

| Inner Frame Height with Press Bar C | 500.3 mm (19.7") | |

| Tabletop Height D | 787.4 mm to 1016 mm (31" to 40") | |

| Front Stopper Distance E | 1803.4 mm (71") | 1397 mm (55") |

| Arch Width F | 2110.7 mm (83.1") | 1709 mm (67.3") |

| Weight | 453.5 kg (1000 lbs.) | 405.9 kg (895 lbs.) |

| Bundle Width | 101.6 mm to 1651 mm (4" to 65") | 101.6 mm to 1244.6 mm (4" to 49") |

| Bundle Height | 20 mm to 480 mm (0.8" to 18.9") | |

| Bundle Length (Min) | 152.4 mm (6") | |

| Bundle Weight (Max) | 49.8 kg (110 lbs) | |