SIG CORR-FLEX

Intuitive System

Fitted with a smart touch system the SIG Corr-Flex is simple to operate

Quick Strap Changes

You can change between strapping and banderole in around 7 minutes

Anti-Strap Loss Function

The ASLF, anti-strap loss function provides easy to use and consistent strap control

Data Analysis

Gather production data analysis so you can make adjustments to enhance plant performance

SIG Corr-Flex

The SIG Corr-Flex an electrical driven bundling press. The bundle stop plate with pre-positioning limits contact when clearing the bundle and the ability to make fast adjustments. Working with polypropylene strapping, the SIG Corr-Flex has an automatic discharge system of remaining strap to maximise strap usage efficiency. Built with GreenTech energy concept to lower energy consumption, this bundling solution works with sustainability in mind, as well as yourself as many optional features including a bundle stop plate for a second strap are available.

Features and Benefits

- Minimise downtime

Downtime is lowered with the Anti-Strap-Loss-Function meaning strap being lost in the machine is easily prevented facilitating longer uptime. Making the machine resilient to malfunction in the packaging process. Also designed with a mono-frame leading to geometric precision for each module; the machine frame encloses the functionality relevant mono-frame creating further resilience. - Sustainable Product

Built with Green Tech, the strapping machine uses up to 50% less energy than conventional machines, supporting your plants sustainability goals and lowering energy consumption providing the same high quality results. - Intelligent System

Attached with an intelligent compression system (ICS) the machine adapts using sensors to the respective products package compaction size. Facilitating modules with high cycle times and higher level user control. Alongside the intelligent compression system, equipped with automatic strap change technology, this option means it is possible to apply a second strap in the event of a fault lowering downtime and enhancing production time. - Intuitive Use

Easy to use Smart Touch 4.0 technology allows operators to make modifications on the control panel all whilst the machine collects data which can be taken for cycle time analysis, maintenance expectations as well as ease of use to the technical documentation of the machine.

Machine Options

- Bundle Stop plate for second strap

- Bundle compensator backside

- Narrower products with a minimum package width of 95mm

- Fully automatic format adjustment making changes in 30 seconds

Technical Specifications

| Specifications | SIG Corr-Flex |

|---|---|

| Single Strap Bundles per minute | 17 Max |

| Parallel Strap Bundles per minute | 12 Max |

| Strap Tension (N) | Up to 400 |

| Strap Material | PP (Polypropylene) |

| Power Supply | Wide Range Input 380-520V, 3AC/N; 47 63 Hz |

| Temperature range in °C [°F] | 5 - 45 |

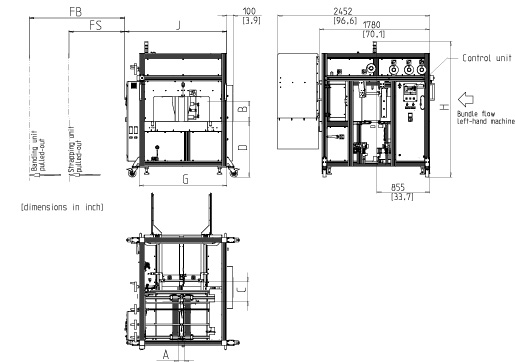

Machine Dimensions

| Details | SIG Corr-Flex 850 | SIG Corr-Flex 1250 |

|---|---|---|

| Arch Size (WxH) (mm) | 850 x 340 | 1250 x 340 |

| Machine Width (mm) | 1410 | 1810 |

| Total Height (mm) | 2110 - 2300 | 2110 - 2300 |

| Table Height (mm) | 820 - 1010 | 820 - 1010 |

| Bundle Width (mm) | 130 - 850 | 130 - 1250 |

| Max. Bundle Height (mm) | 340 | 340 |