Handling Equipment for Metal Industry

Handling Equipment for Metal Coils

Providing multiple handling equipment:

- Integrated Coil Car: Custom designed to handle various sizes of Metal coils, the coil cars are inter-connected, thereby:

- Avoiding empty pit at packaging site.

- Improving throughput as they operate in tandem.

- Promoting safe working environment.

- Coil Car (2 Way) & (4 way): Designed to transfer and rotate wide range of coils, with coil width ranging from 800 mm to 2000 mm. 4 way car includes a baby and mother car, designed to transfer wide width coils in perpendicular direction / bay transfer applications. Therefore making it easier to integrate with coil storage yards.

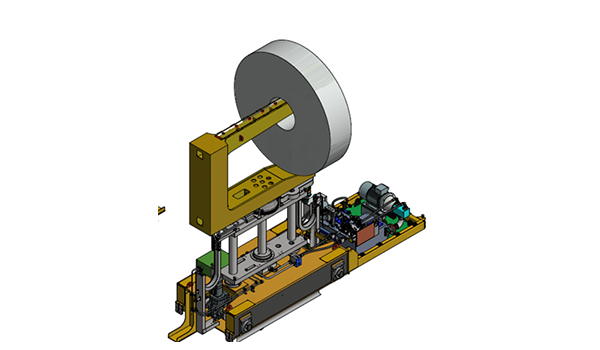

- Goose Neck Coil Car: Goose Coil Cars are designed to transfer and rotating slit coils based on application. Picking is done from the ID of the coils to enhance stability.

- Turnstile: Turnstile handling equipment is designed to accumulate bunch of slit coils from the slitting line and unload single slits for further packing operation.

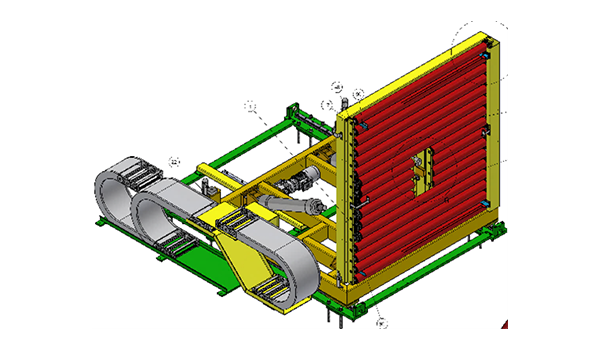

- Downender: Downender a solution designed to change the orientation of the wide width Coil from Eye to Wall to Eye to Sky and vice versa in a packing line. It is also used for palletisation of the Coil.

- Chock Tilter: Chock Tiler is an offline solution designed to change the orientation of Chocks in Rolling Mills from Eye to Wall to Eye to Sky and vice versa.

- Tilter: Tilter is an online solution designed to change the orientation of the Slit Coil from Eye to Wall to Eye to Sky and vice versa in a packing line.

- Picker and Placer: Picker and Placer is an online solution and are custom designed to pick up wide width Coil or Slit Coils in a packing line. Depending on the application the gripper can be Mechanical, Vacuum or Magnetic.

Coil Car

Goose Neck Coil Car

Turnstyle

Chock Tilter

Downender

Tilter

Picker and Placer