Steel Strap with CorroDefend™

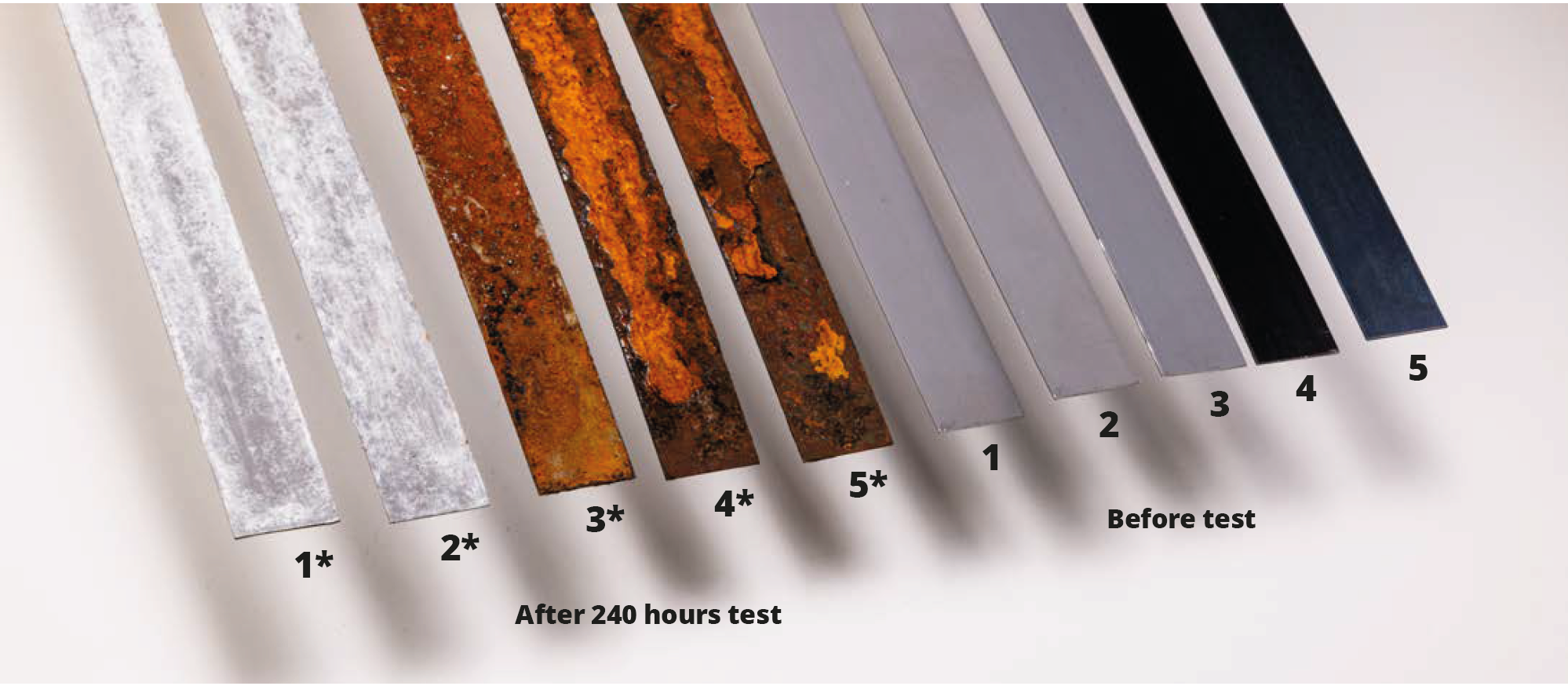

Left: After Test, Right: Before Test

Hot-dip galvanized CorroDefend treatment after 240 hours salt spray test versus control sample.

Anti Corrosion Shield

10+ times resistant to corrosion than standard surface coatings

Designed for challenging conditions

Outstanding resistance to corrosion in damp, harsh conditions associated to long-term or outdoor storage.

100% recyclable

Signode steel strap is made from raw material, that is 100% recyclable.

Produced locally

CorroDefend steel strapping range is produced in Sweden and Germany with the highest quality standards.

Steel Strap with CorroDefend™

CorroDefend coating is applied during production process and acts as an extra layer of protection that will prevent corrosion on steel strap significantly longer than traditional surface coatings. As a result, CorroDefend anti corrosion shield is designed for the most difficult conditions such as moist, harsh environments and temperatures associated with long-term outdoor storage or overseas transports.

Above, Corrosion resistance after 240 hours salt spray test, 1 to 5 after the test 6 to 10 strap before the test, from left to right:

- CorroDefend Hot-Dip Galvanized after 240 hours (1*) compared to control sample (1)

- CorroDefend Electro-Galvanized after 240 hours (2*) compared to control sample (2).

- Zinc painted Surface Finish after 240 hours (3*) compared to control sample (3).

- Black painted Surface Finish after 240 hours (4*) compared to control sample (4).

- Blue Annealed Surface Finish after 240 hours (5*) compared to control sample (5).

Signode Steel Strap - Apex® & Magnus® with CorroDefend™

| Product Specifications* | |

|---|---|

| Width | 19 | 25 | 32 mm |

| Thickness | 0,6 | 0,8 mm |

| Coating | Hot Dip Galvanized is for APEX with CorroDefend, Electrogalvanized is for Magnus with CorroDefend |

| Winding | Ribbon wound, Oscillated |

| Coil Closure | Spot weld / taped / PP Strap |

| Kg/Coil | 28 Kg / 30 Kg |

| Coil Orientation | Laying |

| Coils per Pallet* | 21 |

*Number of ribbon wound coils per pallet depends on dimensions.

| APEX Technical Specifications | |

|---|---|

| Tensile Strength | 800 N/mm2 or [MPa] Avg |

| Break Strength | 9,120 N Avg |

| Elongation A100 | 1% Min |

| Elongation A5 | 5% Min |

| MAGNUS Technical Specifications | |

|---|---|

| Tensile Strength | 1,020 N/mm2 or [MPa] Avg |

| Break Strength | 12,210 N Avg |

| Elongation A100 | 6% Min |

| Elongation A5 | 12% Min |