Octopus®

Signode provides Octopus stretch wrapping solutions based on the rotary ring principle. The first Octopus ring wrapper was sold back in 1983 to a Finnish company wrapping paving stones and blocks, and still today, 40 years after the introduction, the ring wrapping technology is considered market standard throughout the world.

Octopus stretch wrapping equipment is designed for large scale manufacturing operations. Our portfolio of Octopus stretch wrappers provide flexibility and speed to meet the markets ever changing demands. From as few as one to two loads per hour up to 150 loads per hour, we have multiple machine models available to satisfy your exact production requirements.

Discover how Signode can help to find solutions that suit your packaging requirements.

For parts requests please get in touch: parts.octopus@signode.com

For service requests please get in touch: service.fi@signode.com

For HR requests please get in touch: rekry.octopus@signode.com

Unlimited Wrap Patterns and Product Applications

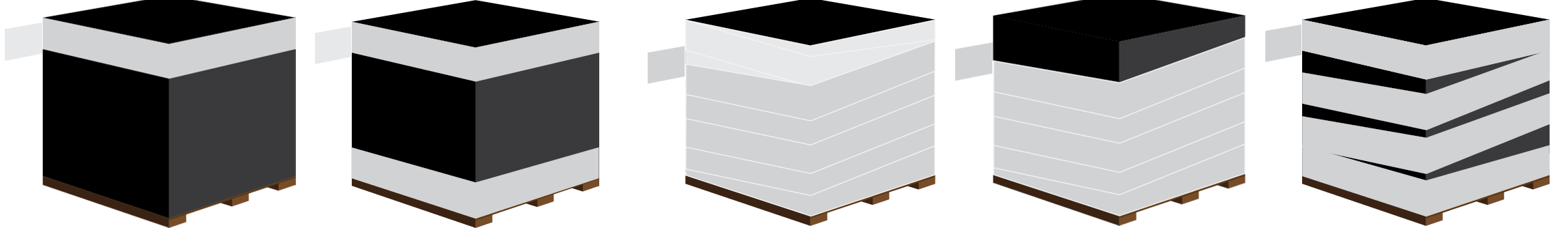

From single wrapping to double wrapping, band wrapping, and flex roping, the Octopus stretch wrappers simplify the wrapping of any load and perform specialized wrap patterns for the most unique load constrains.

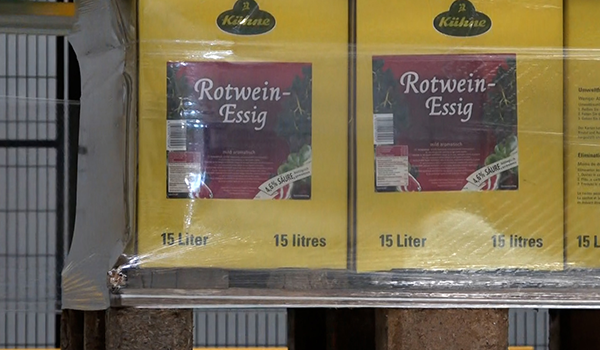

The Octopus stretch wrappers are ideal for wrapping anything from heavy weight bulky building products, to a variaty of boxed goods, to fragile glass and PET bottles within the food and beverage industry.

Features and Benefits

No Touch-No Tail

Virtually eliminates issues due to film unwinding. Seaming unaffected by sharp corners or uneven load surfaces. Practically durable against friction when pallets are loaded side by side during transport.

Film Roping

For increased load stability / improved product to pallet retention. Automatic warehouse compatible.

LogoWRAP

Our option for customer brand recognition - visible from all sides of the pallet. A custom printed film applied under the normal wrapping film layers - protected against normal wear and tear associated with load handling.

Maximum performance at minimum costs

Norms and standards for load stability coupled with changing production requirements make optimizing equipment and film solutions probably more important than ever.

So as a business, how do you accommodate the increased requirements and regulations while ensuring load stabilization at the highest possible level of efficiency and at the lowest possible costs?

At Signode we are uniquely positioned to provide the best total packaging solution for your operation. Signode has its own testing labs featuring ISTA and EUMOS certified equipment. To recreate handling and shipping conditions we have rough handling tests, vibration tests as well as acceleration tests that help determine the rigidity and safety of a load. Our packaging specialists are ready to help from initial assessment of the right packaging solution to testing and proving the solution that provides maximum performance at minimum costs.

Whether you are looking for increased load stability, reduced packaging material, minimum waste, basically an improved packaging process where you can reduce the overall cost of your packaging we can take a close look at your existing solution and make appropriate suggestions and recommendations as to possible cost savings and efficiencies.

Octopus Products

-

Octopus® Prestige™ Stretch Wrapper

High flexibility and speed that meets market standards.

See more -

Octopus® B Series

Low to medium capacity model for various load dimensions.

See more -

Octopus® Compact Series

Compact design requiring less floor space than traditional wrappers.

See more -

Octopus® S Series

Medium and high-capacity model for various load dimensions.

See more -

Octopus® T Series

High-capacity model for various load dimensions.

See more

Other equipment and consumables for wrapping of pallet loads

Besides the Octopus range of equipment Signode offers stretch hood wrapping equipment, strapping equipment as well as stretch wrap films that work in conjunction with our equipment to optimize load containment.

Check out Lachenmeier stretch hooders.

Check out our range of strapping equipment.

Check out our portfolio of stretch wrap film.