AK200

Improves

Productivity

All-electric operation provides a single power source, enabling better control and monitoring

Simplifies

Maintenance

Constructed with few wearing parts along with easy access to all moving and wear parts

Robust

Design

Manufactured with heavy-duty components to withstand varying production conditions

Streamlines

Operation

Built-in features to ensure overall production consistency from cycle to cycle

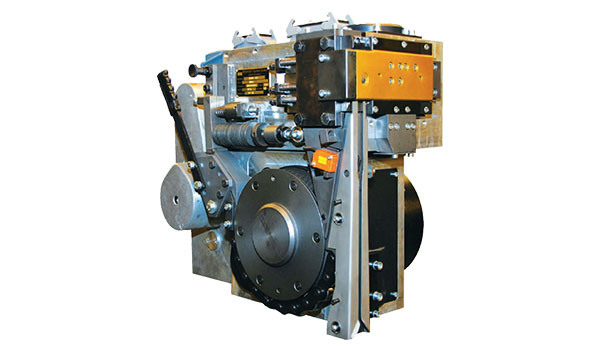

AK200 Strapping Head for Plastic Strapping

Designed for applications that utilize polyester and polypropylene strapping, the AK200, available for standard or heavy-duty applications, is ideal for general packaging as well as stand non-ferrous metals, brick and block, timber and more.

Features and Benefits

- Maximizes performance

The AK200 strapping head combines the superior characteristics of Tenax strapping with Signode’s patented friction-weld technology to ensure reliable and consistent joints for optimal stability throughout the transportation cycle. - Ensures sustainability

The AK200 utilizes plastic strapping that is manufactured with recycled content and is also recyclable. This, coupled with weld technology that eliminates hazardous emissions during cycling, makes the AK200 an environmentally-friendly option. - Maintains production consistency

Standard features like a large feed and take-up wheel ensure optimum strap feed and consistently high applied strap tension.

Technical Specifications

| Electrical Requirements | 480V 3 Ph 60 Hz 400V 3 Ph 50 Hz |

| Minimum Pack Face | 150 mm (5.91") |

| Optional 90 mm and 120 mm (3.54" and 4.72") | |

| Strap Feed and Take-Up Rate | 1.25 m/second (4.10 ft/second) |

| With optional inverter 3 m/second (9.84 ft/second) | |

| Strap Tension | Variable up to 4500 N (1011.64 lbs) |

| Strap Type | Tenax® polyester strapping |

| Strap Width | 12 mm, 16 mm, 19 mm, 25 mm, 32 mm (1/2", 5/8", 3/4", 1", 1-1/4") |

| Strap Gauge | 0.5 mm – 1.27 mm (0.019" - 0.039") |

| Joint Type | Friction weld |

| Strapping Head Weight | 92 kg (203 lbs.) |

| Joint Strength | Meets ASTM D-3950 |