M247

Maximizes

Uptime

Interchangeable modular components can be quickly removed and replaced for routine maintenance

Improves

Productivity

Innovative all-electric design provides consistent high strap tension levels for optimal package performance

Simplifies

Integration

Easily installed into existing equipment and OEM operations

Streamlines

Maintenance

Built-in diagnostics help with troubleshooting to minimize production interruptions and downtime

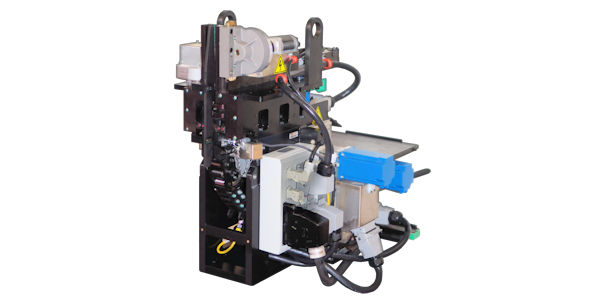

M247 Modular Strapping Head

From circumferential coils to bar and tube bundles, the M247 provides reliable performance and reduced downtime for heavy-duty steel strapping applications. Unlike other comparable systems, the M247 has a single power source to enable better control and monitoring of functions to maximize uptime.

Features and Benefits

- Cost-efficient design

The M247 features a simple design with few moving parts and highly durable wear parts, making it more cost efficient to maintain than traditional steel strapping heads. - Innovative modular technology

Interchangeable modular components can be quickly removed and replaced for routine maintenance with no need for special handling equipment. Modules can be replaced inline by customer service personnel, eliminating long-term service disruptions and minimizing operator exposure to active machinery.- Equipped with locator plates or latches for precise alignment

- No tools necessary for removal

- Spare modules can be kept on hand for maximized uptime

Technical Specifications

| Electrical Requirements | 400V, 50 Hz, 3 Ph 460V, 60 Hz, 3 Ph |

| Minimum Pack Face | 150 mm (6.0") |

| Strap Feed Speed and Take-Up Rate | 0.5 - 2.1 m/s (1.64 - 6.9 ft/s) |

| Strap Tension | 9500 N- 22500 N (2,135 lbs. - 5,620 lbs.) |

| Strap Type | Apex® regular duty and Magnus® heavy duty |

| Strap Width | 32 mm (1.25") |

| Strap Gauge | 0.8 mm - 1.1 mm (.029" to .044") |

| Seal Type | Double notch |

| Joint Strength | Meets ASTM D-3953 |

| Strapping Head Weight | 250.3 kg (550.7 lbs.) |