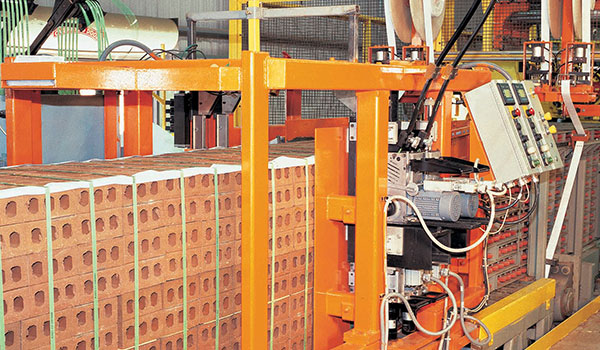

Z-20 Brick Packaging System

Maximum

Productivity

By moving the strapping head from the top of the cube to the side, we’ve reduced the cycle time from nine and one-half seconds to six seconds.

Ease

of Use

Operators can now access all necessary components without the use of heavy equipment or having to climb on top of the machine.

Minimizes

Downtime

The Z-20 can accommodate special production runs without making any strapping head adjustments, saving valuable time.

Easy

Maintenance

Constructed with fewer moving parts and more durable wear parts, the Z-20 is more cost-efficient and easier to maintain.

Z-20 Brick Packaging System

The Z-20 modular strapping system is designed to reduce maintenance costs and accommodate faster production speeds, the Z-20 integrates Signode’s latest strapping technology into a simple to operate and maintain brick packaging system that can improve profitability and reduce downtime for your operation.

The Z-20’s innovative modular design consists of separate sealing and tensioning modules each weighing less than 60 lbs. These lightweight, compact modules are easy to access and can be changed out quickly for routine maintenance, eliminating any downtime. When switching to a spare module, typical brick packaging stations can be up and running in less than a couple of minutes. No lifting device or special handling equipment is required.

Features and Benefits

- Tighter, protected brick cubes

By placing the strapping head on the side of the brick cube, a greater amount of tension can be applied to create a tighter, more uniform brick cube with higher retained tension. This provides increased stability to prevent brick cubes from sagging when transported by fork truck across rough terrain. - More reliable

Having the Z-20’s strap joint placed on the side of the cube prevents joint breakage when sliding one brick cube across the top of another. The Z-20’s proven sealless Z-weld friction joint yields superior shear strength and peel resistance to withstand even the toughest impacts without breaking. - No adjustments needed

Regular brick packs and half-packs can be interchanged during production runs without the need for changes or adjustments. - Easier to maintain

There are no belts, pulleys or tolerances to worry about. Easy access to the strap path allows any operator to keep the system clean without special training or experience. Strap chutes are fixed for additional durability.

Technical Specifications

| Strapping | 16mm width x 0.76mm to 1.00mm gauge 19mm width x 1.00mm to 1.50mm gauge |

| Rate of feed | 10 feet per second (3.1 meters per second) |

| Rate of take-up | 10 feet per second (3.1 meters per second) |

| Strap tension range | 200 to 1,000 lbs (890-4450N) |

| Electrical requirements | 230 volt, 60Hz, 3 phase 400 volt, 50Hz, 3 phase 460 volt, 60Hz, 3 phase |

| Tensioning module | Height: 16" (405mm) Width: 16" (405mm) Depth: 7-1/2" (190mm) Weight: 60 lbs (27kg) |

| Sealing module | Height: 15" (380mm) Width: 9-1/4" (235mm) Depth: 6-1/2" (165mm) Weight: 37 lbs (16.7kg) |