Carbonated Drinks

Signode provides solutions to handle packaging and protective shipment of carbonated beverages. Explore our solutions to secure produce before and for shipment while improving handling efficiency.

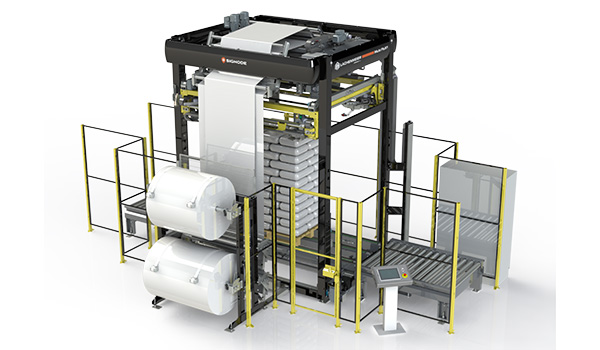

Wrapping & Hooding Solutions

Wrap multipacks of cans or bottles tightly to prevent shifting during transport, important to palletize these loads securely to minimize product wastage during transportation. Wrapping not only offers stabilisation support but protects from dust, moisture, and contamination. Featured solutions including the Octopus® T and Lachenmeier ® hooders.

Octopus T

Octopus T

The Octopus T is developed for high-speed production lines, manufactured with a heavy duty steel frame for an efficient performance. The T series simplifies integration with increased speed facilitating the ability to run multiple lines through a single line.

Lachenmeier Hooders

Protect beverages from the elements applying stretch hood with capacities up to 200 pallets per hour (depending on load size), optimise performance according to film size and thickness for required load stability.

Strapping for Carbonated Drinks

Prevent load shifting and reduce damage from handling and vibrations during shipment, utilise Signode strapping to support to secure cases, hold multiple beverage cases together on a pallet you can also bundle smaller packs of bottles or cans into larger retail units. Often used with edge protection to protect boxes of drinks.

Signode provides strapping hand tools, and equipment to support palletisation for use with both PP or PET strap. Use PP strap, a reliable and economical choice for securing carbonated beverage cases and pallets, especially in short-distance shipping or warehouse storage.

Protective Packaging for Carbonated Drinks

Use Top Frames and Tier Sheets protecting loads of cans and bottles when palletizing. Top Frames are a rigid frame placed on the load to support stability and handling of cans and bottles. Tier sheets are to be placed between layers of bottles or cans and aim to stabilize, protect the product and evenly distribute the weight of loads.

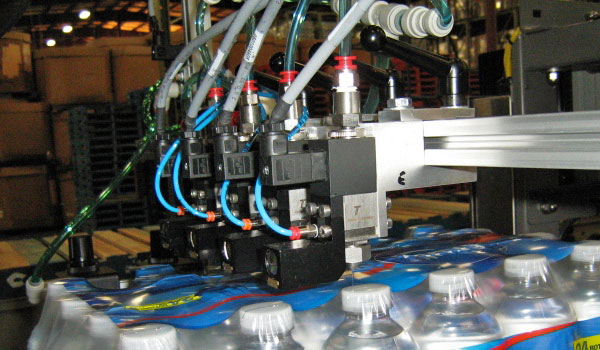

LOCK N' POP

LOCK N' POP cohesive, non-toxic and water-based, secures packages together to eliminate side-to-side shifting, providing greater load stability throughout the transportation cycle. Providing an alternative to strapping and wrapping where you create a temporary bond between layers of packaging, improving stability while being easy to separate when needed. Maintain effectiveness even in cold storage or humid environments.

Signode Solutions for Carbonated Drinks

Get in touch with Signode to discuss our variety of solutions on how to best package carbonated drinks to protect against damages, stabilize loads and improve overall packaging efficiency.