Lachenmeier

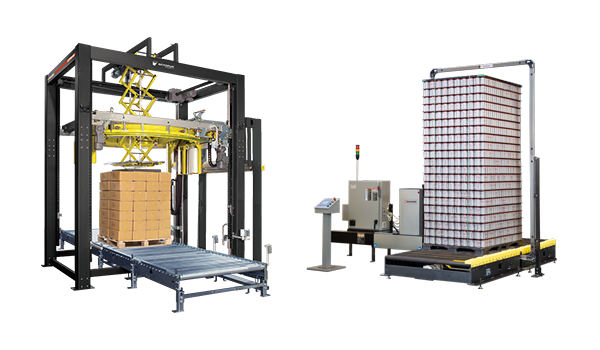

Signode proudly provides Lachenmeier stretch hood wrapping solutions for customers around the world. We design, manufacture, and integrate simple and yet highly efficient stretch hood wrapping solutions to help solve the complex challenges in end-of-line packaging.

We focus on machine performance in combination with the right packaging film and we look for cost saving opportunities while finding ways to reduce film usage and to improve the quality of the wrapping.

Discover how Signode can help identify your unmet packaging needs and find solutions that suit your packaging requirements by contacting us today.

For parts requests please get in touch: parts.lachenmeier@signode.com

For service requests please get in touch: service.dk@signode.com

For HR requests please get in touch: hr.dk@signode.com

For Multiple Product Applications

We have over 40 years of experience working with diverse industries to deliver packaging solutions that help increase your company’s efficiency as well as bottom line. With a deep understanding of customer products and requirements, our solutions help solve complex packaging challenges.

From palletized goods in the food, beverage and pharma industry, to bricks, blocks and pavers in the construction industry, to bagged commodities in the chemical industry, to insulation material and products in the appliance industry, the list of applications continues.

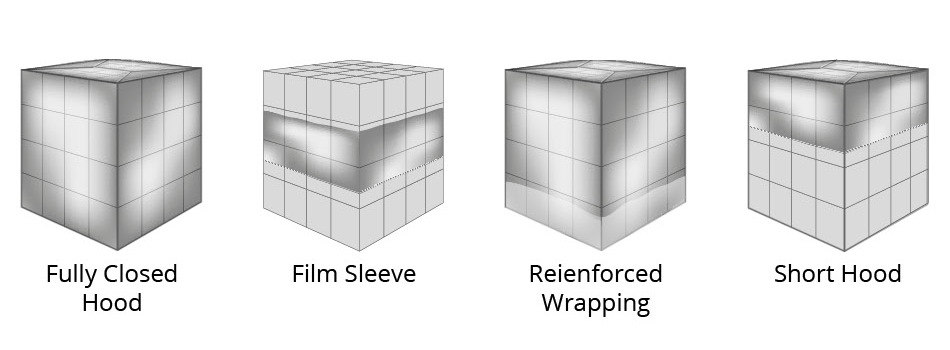

Wrapping Patterns

Multiple wrapping patterns allow wrapping using either a fully closed hood to film sleeves and short hoods, as well as film reinforcements applied where needed on the load for improved load stability.

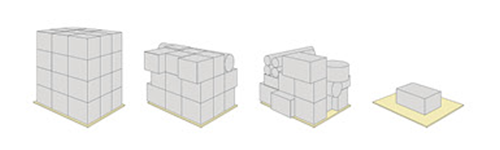

Load Palletizing Versatility

The Lachenmeier stretch hooders accommodate variable load sizes and types, from fully cubed loads and irregular loads to a single box on a pallet.

Pallet Load Testing

Your company produces great products. But even a great product – if it is not packed correctly before being transported, can incur extra costs, and weaken customer confidence in your brand.

Signode offers a unique testing program opportunity for committed customers to witness and experience first hand the performance of our products. Whether you are looking for increased load stability, reduced packaging material, minimum waste, i.e., an improved packaging process, we can assess your current wrapping solution and identify opportunities for packaging improvements that support your business needs.

Our packaging specialists are ready to help from initial assessment of the right packaging solution to testing and proving the solution that provides maximum performance at minimum costs. If you question whether your pallet wrapping provides you maximum performance at minimum costs then contact us for a possible test wrapping and an assessment of your current wrapping process.

Lachenmeier Products

-

Multi FleX1

The machine can wrap a variety of load sizes and is easy to integrate into existing packaging lines. Wrapping 200 units/hour. Service at floor level. (Available as Electric model).

See more -

Multi FleXL

For large format wrapping. You can configure it with 4 film rolls. Selects film size with excellent fit for each load size. Service at floor level.

See more -

Power Flex T1

Mainly for wrapping of one pallet size or pallets with minor differences in size. Small footprint. Top down feature for servicing at floor level.

See more -

Power Flex TL

For pallet sizes with minor variations in size. Transparent film for high product visibility. You can apply printed films. Service at floor level.

See more

For Multiple Product Applications

Besides stretch hood pallet wrapping equipment, Signode offers stretch wrap and strapping equipment for wrapping of pallets loads.

- Check out our stretch wrapping range.

- Check out our strapping portfolio.