SP-304

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

Increases Productivity

"T"-rail pack station and flap folding assist can increase output as much as 40% over hand sealing

Minimal Setup

Quick and simple width & height adjustments

Enhanced Performance

Patented single mast design allows clear access

Simplifies Operation

Self-centering belts and lubrication-free tape cartridges for easy operation

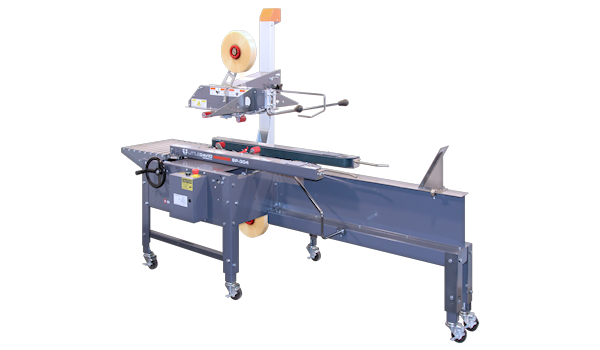

SP-304 Semi-Automatic, Uniform Case Sealer

The SP-304 semi-automatic case sealer with packing anvil is a complete ‘end of line’ solution. It improves end of line speed and efficiency by removing the need to fold six of the eight flaps on the case. This results in outcomes that are up to 40% more effective than hand sealing. The SP-304 case sealer uses simple adjustments and no air or pneumatics are used in the machine, which makes it reliable, simple and portable.

The SP-304 case sealer is side-belt driven, and it operates by propelling cartons through a folding section that folds all major flaps and one upper flap. Repetitive motion from hand sealing is reduced, and productivity is increased with this innovative design.

Features and Benefits

Performance

- Plug-in operation

- Minimal operator training required

- Self-centering belts

- Alleviates twisting motion known to cause carpal tunnel syndrome

- Patented single mast design allows clear access

- Knife guard system of the CaseLocker ST™ tape cartridge allows the blade to be exposed only when the rollers have been depressed

Versatility

- Tapes boxes from 114 mm (4-1/2 in) to 610 mm (24 in) in height

Durability

- Sealed drive system

- CaseLocker ST™ tape cartridge requires no lubrication

Optional equipment

- Exit roller transfer table

- Casters

- Recommended spare parts kit

- Spare Caselocker 60™ tape cartridge

- Jet printer adapter

- Mirror image (left to right case flow)

- Additional sized "T" rail (slide on)

- Hold-down sled

- Additional length "T" rail

- Extended box guides (12")

- Permanently change conveyor height

- 34" high case capability (type II)

- 3 phase motor

- NEMA 4 or NEMA 12 electrical package

Technical Specifications

| Power | 110 volts, 60 cycle, single phase |

Operating Speed | 21.9 m/min (72 feet) per minute)* |

Case Range | Length: 152.4 - 609.6 mm (6 - 24 in) Width: 114.3 - 508 mm (4.5 - 20 in) Height: 114.3 - 609.6 mm (4.5 - 24 in)** |

| Machine Dimensions | 2019.3 mm (79-1/2 in) long 1092.2 mm (43 in) wide 1720.8 mm (67-3/4 in) high |

| Weight | 136 kg. (300 lbs), uncrated |

Conveyor Height | 615.9 - 742.9 mm (24-1/4 - 29-1/4 in) Standard Consult factory for other heights |

| Warranty | 3-year - Tape cartridges 2-year - Complete drive system, motor/gear reducer 1-year - All other parts except for wear and moving parts |

| Closure Material | Pressure sensitive tape |

* Production rate depends on box size & operator dexterity

** Certain length x width x height combinations may not process due to unstable conveying conditions

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport