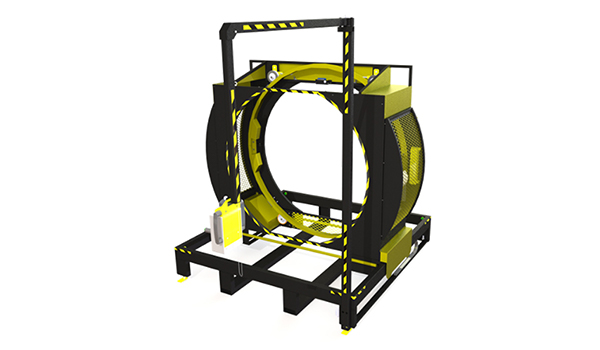

Yellow Jacket 87 Semi Automatic

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport

Regional Availability

Robust Construction

Steel frame structure provides efficient performance, long life and minimal maintenance.

Production Flexibility

Accommodates variable load sizes to satisfy packaging challenges.

Operator Friendly Features

Simple, intuitive push button machine controls ensure ease of use for all operators.

Safety as a Standard

Designed to comply with current national safety and regulatory standards.

The Signode Yellow Jacket 87-SA Orbital Stretch Wrapping Machine

Our stretch wrappers provide our clients with a durable and efficient means of product transport. Choose from options that fit your needs as well as your budget. Secure shipments of all sizes and shapes quickly with little or no manual labor involved. Wrapping pallets by hand before shipping requires multiple employees, and it can be a time-consuming process. Every day, companies are switching over to automated pallet wrapping methods and are reaping the benefits of them. These systems cut down costs because they need only one operator, and they increase production speeds dramatically. The Yellow Jacket secures pallets of varying dimensions without the need for additional resources.

The Yellow Jacket 87-SA orbital stretch wrap machine is perfect for securing over-sized, oddly shaped, palletized loads while the pallet is on the forklift. The horizontally positioned stretch wrap dispenser moves around and under the load as the Yellow Jacket automatically moves across the length of the load. This process significantly cuts down on the time it takes to wrap a load by hand. Two workers will take about 10 minutes to wrap a load by hand. With the Yellow Jacket, one worker can wrap a similar load in 1 minute. This creates a reduction of labor cost by at least 50%. Yellow Jacket also eliminates the need for other strapping materials and expensive cartons to secure loads. Tightly wrapped to the pallet, the load’s ability to shift, fall, or slide in transit is nearly impossible.

Features and Benefits

- Operator controls entire wrapping process and all machine functions from the seat of the forklift

- Joystick remote control allows for ease of use

- Simple operator training to allow them to work the machine efficiently

- Machine can run up to 20 revolutions per minute

- Full control of where to start and stop wrapping cycle

- Maintenance free gear box is economical to maintain

Technical Specifications

| Maximum Load Capacity | 68 1/8" |

| Maximum Wrapping Length | 77" |

| Machine Dimensions | 91" x 93" x 95" |

| Power Requirements | 110 volt |

| Ring Speed | 5 - 20rpm |

| Controls | Push Button |

| Film Type | Standard 20" Machine Grade Film |

| Film Delivery | Core Brake w/Adjustable Tension |

| Portability | Fork-Lift Portable |

Solution Group

- Products

- Services

- Integration

- Automation

-

pack

-

bundle

-

unitize

-

warehouse

-

transport